Indicators on Logistics Companies Near Me You Need To Know

Wiki Article

Shipping - Truths

Table of ContentsA Biased View of Logistics Companies ProcessOur Logistics Companies Process StatementsEverything about Freight Logistics CompaniesLogistics Services Can Be Fun For Anyone

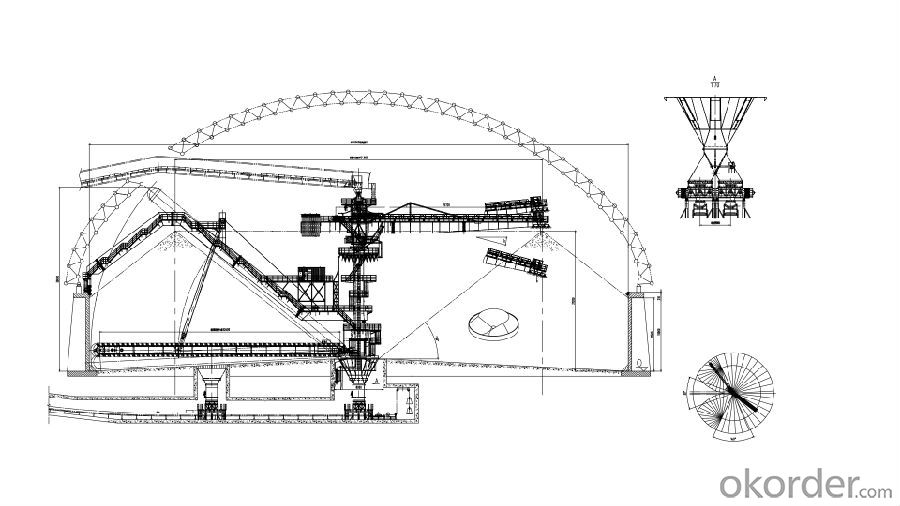

Wherever mass material is managed, Sandvik Mining's Item Area Mining Solution will certainly exist. In enhancement to satisfying the needs of the mining sector, the business additionally stands out in meeting the needs of downstream procedures, such as power plants and mills, ports and terminals with an approach tailored for each and every application.As buffering, making up and also homogenizing done by a stockyard can differ quantity along with high quality fluctuations can be stabilized out with the correctly chosen system. logistics companies. As the top priorities for each application as well as stockyard operations are different, it is required to take into consideration different concerns prior to picking type and also dimension: throughput required, attributes of the products to be managed, homogenizing impact needed, open or roofed storage space and importantly, the future upgrading of the storage space.

For collision evasion systems it may be required to allocate the sensing units against various other moving targets whereas for stockpile profiling they scan a strong ground and also map its specific shape by producing 3D images, which are saved in a stock database. "The essential requirements of the systems is the toughness of the sensing units, rapid signal action and dependable measuring leads to order to enhance the device accessibility and to maintain high performance degrees of the devices under all functional conditions," claims Branco Lalik, Product Manager for Materials Handling, Sandvik Mining Equipments.

Logistics Companies Process Things To Know Before You Buy

They will certainly be incorporated right into the Sandvik in-house developed PLC software program as well as the corresponding SCADA system. For safe, affordable, high-volume stockpiling, a Wisconsin, USA-based construction aggregate manufacturer has actually replaced pricey loader use with a 580-foot tripper conveyor. From April to November, Wissota Sand & Crushed rock stockpiles product 24-hours a day. "We fill out trucks 52-weeks a year, however we can only create product when Nature allows us," states Dennis Simniok, a 30-year industry veteran that is manager of the firm's Milwaukee, Wisconsin, U.S.A. pit.Today, the site flaunts a 580ft (177m), pillar-supported, tripper conveyor, among the longest and tallest in the area. The custom-made system was manufactured by Superior Industries of Morris, Minnesota, United States. There are a great my company deal of elements that led the operation to changing loader use with a tripper conveyor system, among one of the most vital being safety and security.

Not just does it require time and more helpful hints work to construct as well as berm a ramp for stockpiling, it results in significant product loss. logistics services. Simniok emphasizes that also if it were risk-free for a loader to consistently add and down a ramp, it takes an incredible quantity of material to build the ramp and also after that you finish up with a polluted stack.

Pretty soon, the ramp is all filthy as well as you have less sellable item. When you load vehicles in the winter months, you can just pack back to the ramp and after that you've got to back away from it because the ramp is dirty and you can't load out that material. Every spring, you have this unclean ramp to deal with product which you can only sell to sewage system professionals at a cut price," he states.

Some Of Transport And Logistics Companies

So we would generally place a number of extra loaders on stockpiling for a several hours you can try these out at the end of the day, so that one loader might stay up to date with the task during the night. What's even more, you need to think about that each loader is stockpiling one bucket at a time.

We really had to take a close check out the price of running these makers," says Simniok. Simniok says that they decided to place in a tripper conveyor due to website restrictions which asked for a long, narrow, yet high-volume stockpile to meet need. Standard radial stackers would certainly not be able to do the task.

"What we wound up with is a tripper conveyor system that runs unattended and accumulations at 450 brief bunches (408 statistics tonnes) per hr with no man hrs, no equipment, as well as no fuel. Obviously, today's gas rates are triple what they were when we began up the system 3 years earlier.

The Single Strategy To Use For Logistics Companies Transportation

Trippers are tools that release material from a belt conveyor at points upstream from the head sheave. A tripper consists of a frame supporting 2 idling sheaves, one over and forward of the other.The conveyor belt itself drives a normal movable tripper, by an electric motor, or by a wire and also winch. The tripper relocates an ahead and also turn around direction to make a lengthy stack on one, or on each side of the belt conveyor. "Superior Industries created a tripper conveyor style that actually fits our needs," claims Simniok who details the complying with parameters: v continuous procedure; a remote-controlled tripper automobile; remote-controlled discharge from one side to the other; capacity to be mounted on 57-foot-tall (17m) concrete columns; 30-inch (76cm) belt; capability to cover a minimum of 60-feet (18m) between columns; efficient in developing a big-volume accumulation of at least 180,000 brief loads (163,293 statistics tonnes); ability to manage 450 short heaps per hour (408 metric tonnes) of wet material without the head pulley-block rotating out Simniok says that they selected the Superior Industries style over the competitive bids because of the integrity of its structure.

Report this wiki page